University of Massachusetts mechanical engineering seniors Max Perham, Nate Fowler, Andrew Dodd and Greg Kelley are headed to the Marshall Space Flight Center in Huntsville, Alabama on April 7 for six days to launch their rocket with other colleges and universities across the nation.

The project began in the late spring of their junior years, in which the four wanted to work on their honors thesis project that involved competition design and rockets, which all members had an interest in but had minimal experience with.

After doing some research, Perham, the team leader, found the NASA Student Launch Challenge, which is an annual rocket competition for high schools, colleges and non-academic teams across the country. The research and experiment results are used in future designs for NASA projects.

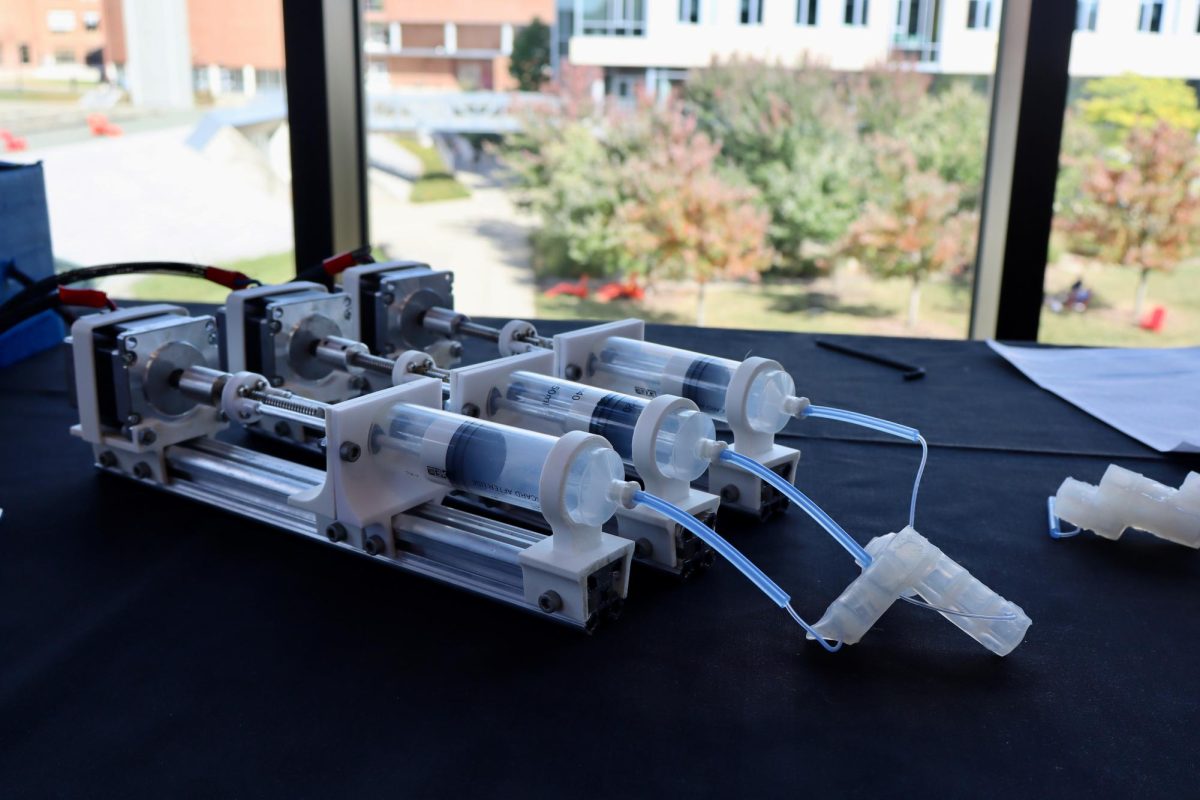

Each year, the NASA Student Launch presents a different challenge, and this year’s mission is to stimulate a robot picking up a sample of Martian soil, loading it into the rocket, manually launching the rocket at least 3000 feet into the air, 10 times the height of the W.E.B. DuBois Library, and having the sample soil and the rocket break off and independently land with their own parachutes, all intact and reusable.

Kelley said one of the most difficult challenges to this project was just getting started.

“We didn’t have supplies, money or even a workspace,” he said. “We talked to the development office, which is in contact with the alumni to give donations, and they were able to give us a little bit of funding. Most of our funding came from us applying to honors research grants.”

The group benefitted from the mechanical and industrial engineering student space, which allowed them to start building the rocket in the hopes that the school will provide more funding in order to ensure other students can keep on using this space as well.

For the past year, the four seniors have been working on their rocket, Sam, which is almost 10 feet in length, four inches in diameter, is made up of four independent sections and weighs about 23 pounds.

The National Association of Rocketry does not allow for heavy metals to be used, for safety reasons, so the team’s rocket is made with 3D printer parts and the body is made of vulcanized phenolic tubing, a high strength paper tube with rubber coating.

Before they were even able to work on Sam, however, they had to make preliminary designs that were checked over with NASA, and had to build several rocket prototypes as well.

The team was put at a slight disadvantage because none of the members had worked with high powered rocketry before. They had to learn new concepts such as coding and multitasking to build the robot, and as Dodd said, “Code is a bit a scary.”

Fowler added, “In our classes we learn very specific individual things, but this project brings everything together, where we identify the problems and what on the rocket needs to be optimized or needs to be better.”

Each of the teams also needs a mentor who is a member of the NAR that is certified, and the team’s mentor was Howard Greenblatt of the Central Massachusetts Spacemodeling Society. The team said they are thankful to him because without him they wouldn’t have gotten as far as they are now.

Another requirement of the NASA project is that each team needs to do educational outreach to promote STEM education. The Minuteman Launch Team worked with Amherst Regional Middle School, gave a presentation and has done one-on-one water-powered rocket building with them as well.

Perham said that overall, this project was challenging, but beneficial.

“If you really want to do something on this campus, you can make it happen,” he said. “But you’re going to have to put some time into it.”

Christina Yacono can be reached at [email protected].

VJ • Apr 11, 2015 at 1:49 pm

Nice writeup. It’s good to see UMASS getting into space and rocket technology.

lol • Apr 3, 2015 at 1:00 am

“They had to learn new concepts such as coding and multitasking to build the robot,…”

multitasking

multitasking

multitasking