Now, some of that money is coming to support the work of one engineer at the University of Massachusetts who is trying to understand the fundamental science of fuel cells and use that knowledge to suggest ways to make them less expensive and more efficient.

Ashwin Ramasubramaniam, assistant professor of mechanical and industrial engineering, has been awarded a five-year $750,000 grant from the U.S. Department of Energy (DOE) to study the nanoscale materials inside fuel cells. The money will be used to support doctoral and post-doctoral researchers.

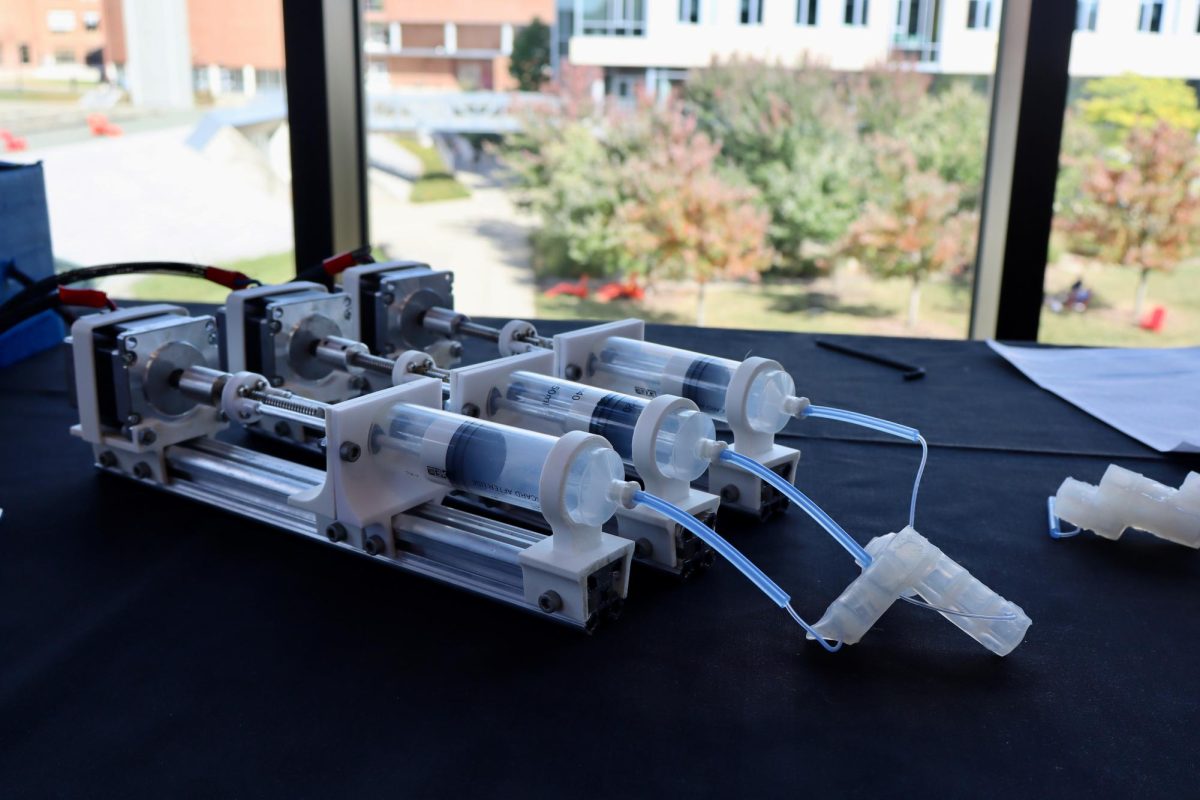

A fuel cell is an electrochemical device that combines hydrogen and oxygen to generate electricity. Fuel cell technology is an attractive alternative energy source because the reaction produces water and heat as byproducts, instead of greenhouse gases like the carbon dioxide released from burning gasoline. A fuel cell vehicle also has a greater driving range and is more efficient than a battery-powered one.

Fuel cells, however, are expensive. Ramasubramaniam said many of them rely on rare metals, like platinum, which are used as catalysts to speed up the rate of chemical reactions. In this research project, he will use computer modeling to design and evaluate improved ways to use this costly material.

The key is to minimize the amount of material while maximizing its surface area. If you have a brick of platinum, for example, most of its atoms are sitting inside where they are not helping out with the reactions. Ramasubramaniam said you want the surface-to-volume ratio to be as high as possible in order to increase the number of reaction sites.

“So instead of taking one, big block of platinum, you take a lot of small clusters of the same thing,” Ramasubramaniam said. “You’re using the same amount of mass, but now you’ve got way more surface area.” .

The assistant professor will also be looking into the material that these small pieces of platinum are anchored to, usually thin sheets of carbon atoms arranged in a honeycomb lattice called graphene. Ramasubramaniam said graphene is more effective in fuel cells than other commonly used carbon supports. He wants to know why platinum and graphene work so well together.

Once he has answered these basic questions, Ramasubramaniam can explore new ways of optimizing these materials. This could mean using lesser amounts of platinum or replacing it with another metal altogether.

Ramasubramaniam is studying nanoparticles, which are so small that you need a powerful and specialized microscope to even see them. A nanometer is one billionth of a meter. According to the National Nanotechnology Initiative, that means a single sheet of paper is roughly 100,000 nanometers thick. A single nanoparticle is one million times smaller than an ant. Working with materials on a nanoscale has been a major research focus because matter takes on unique properties at this level. Platinum, gold and silver are the least reactive metals in their normal, solid state. Shrink these elements down to nano size, however, and you can use them to catalyze chemical reactions inside fuel cells.

Ramasubramaniam says precision is important when working on a nanoscale.

“While changing the physical dimensions of these clusters, you’re also subtly changing their chemical properties and so you have to be careful in trying to understand how exactly this is going to affect the rates of reactions,” he said.

When the materials are scaled up to a visible size again, a single fuel cell produces a very small amount of electricity by itself. In a fuel cell vehicle, you might have hundreds of these individual cells linked up inside a fuel cell stack. This is part of the reason why fuel cells are so expensive.

The government’s support of research like Ramasubramaniam’s has driven down the cost of fuel cell transportation systems, from $275 per kilowatt in 2002 to $47 per kilowatt in 2012, according to data from the Energy Department’s Fuel Cell Technologies Office.

Earlier this month, the department announced a combined $4.5 million investment in projects at the 3M Company and the Colorado School of Mines, an engineering university, to improve the efficiency of fuel cells.

At UMass, the project is being funded through the Energy Department’s Early Career Research Program, which Ramasubramaniam, 36, said, “funds people like me, who are still starting up their research careers and getting going.”

The Energy Department’s Office of Science received more than 700 grant applications from university and national laboratory researchers from all over the country. Ramasubramaniam’s proposal was selected along with just 60 other scientists who submitted their projects for consideration.

Although the funding program is highly competitive, it allows young researchers to compete against others on their own level. The Early Career program aims to provide “support to exceptional researchers during the crucial early career years, when many scientists do their most formative work,” according to an Energy Department press release announcing the awardees.

Ramasubramaniam came to the United States after graduating from the Indian Institute of Technology in Mumbai, India, because he feels the graduate education system is superior here than in other parts of the world. After completing his graduate studies at Brown University, he joined the engineering department at UMass, where he has found the large school to be a valuable venue for scientific collaboration.

“There are groups of people all over the place doing extremely interesting and high quality work and I get to interact with all of them,” he said.

David Barnstone can be reached at [email protected].